I-Carbon Steel Hex Bolt Din 933

| Igama lemikhiqizo | I-CARBON STEEL HEX BOLT DIN 933/ISO4017 |

| Okujwayelekile | I-DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Ibanga | Ibanga Lensimbi: I-DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; I-SAE: Gr.2,5,8; I-ASTM: 307A, A325, A490, |

| Ukuqeda | Zinc(Ophuzi,Omhlophe,Oluhlaza okwesibhakabhaka,Mnyama),Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel plated,Zinc-Nickel plated |

| Inqubo Yokukhiqiza | I-M2-M24:I-Cold Froging,M24-M100 Hot Forging, Imishini kanye ne-CNC yesibambiso esenziwe ngokwezifiso |

| Imikhiqizo eyenziwe ngezifiso Isikhathi sokuhola | Izinsuku ezingama-30-60, |

| Amasampuli wamahhala we-fastener ejwayelekile | |

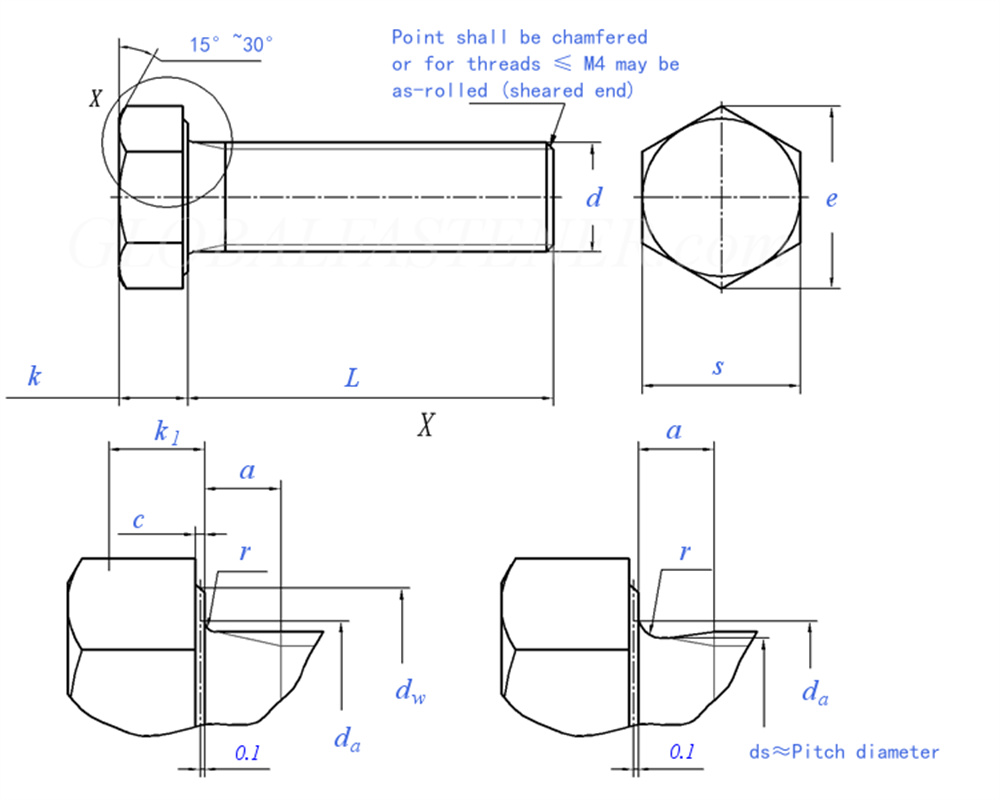

| I-Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Iphimbo | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| a | ubuningi | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 4 | 4.5 | 5.3 | |

| imiz | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | ||

| c | ubuningi | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| imiz | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | ubuningi | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| dw | Ibanga A | imiz | 2.27 | 3.07 | 4.07 | 4.57 | 5.07 | 5.88 | 6.88 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Ibanga B | imiz | 2.3 | 2.95 | 3.95 | 4.45 | 4.95 | 5.74 | 6.74 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Ibanga A | imiz | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Ibanga B | imiz | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| k | Usayizi Wokuzisholo | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Ibanga A | ubuningi | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| imiz | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Ibanga B | ubuningi | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| imiz | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Ibanga A | imiz | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Ibanga B | imiz | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | imiz | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | ubuningi=usayizi wegama | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Ibanga A | imiz | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Ibanga B | imiz | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| I-Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Iphimbo | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| a | ubuningi | 6 | 6 | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | |

| imiz | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | ||

| c | ubuningi | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| imiz | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | ubuningi | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| dw | Ibanga A | imiz | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Ibanga B | imiz | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Ibanga A | imiz | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Ibanga B | imiz | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| k | Usayizi Wokuzisholo | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Ibanga A | ubuningi | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| imiz | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Ibanga B | ubuningi | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| imiz | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Ibanga A | imiz | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Ibanga B | imiz | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | imiz | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | ubuningi=usayizi wegama | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Ibanga A | imiz | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Ibanga B | imiz | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| I-Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 | ||||||||

| P | Iphimbo | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | |||||||

| a | ubuningi | 13.5 | 15 | 15 | 16.5 | 16.5 | 18 | |||||||

| imiz | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | ||||||||

| c | ubuningi | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

| imiz | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||||||||

| da | ubuningi | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 | |||||||

| dw | Ibanga A | imiz | - | - | - | - | - | - | ||||||

| Ibanga B | imiz | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 | |||||||

| e | Ibanga A | imiz | - | - | - | - | - | - | ||||||

| Ibanga B | imiz | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |||||||

| k | Usayizi Wokuzisholo | 28 | 30 | 33 | 35 | 38 | 40 | |||||||

| Ibanga A | ubuningi | - | - | - | - | - | - | |||||||

| imiz | - | - | - | - | - | - | ||||||||

| Ibanga B | ubuningi | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 | |||||||

| imiz | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | ||||||||

| k1 | Ibanga A | imiz | - | - | - | - | - | - | ||||||

| Ibanga B | imiz | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 | |||||||

| r | imiz | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 | |||||||

| s | ubuningi=usayizi wegama | 70 | 75 | 80 | 85 | 90 | 95 | |||||||

| Ibanga A | imiz | - | - | - | - | - | - | |||||||

| Ibanga B | imiz | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |||||||

Izici Nezinzuzo

I-Carbon Steel Hex Bolt Din 933: Isixazululo Sezidingo Zakho Zokuqinisa

Uma kuziwa ekubopheni, ufuna isixazululo esiqinile, esithembekile futhi esilula ukusifaka. I-Carbon Steel Hex Bolt Din 933 imaka wonke amabhokisi alungile ngokunikeza ibhawudi eliqinile neliguquguqukayo elingasetshenziswa ezinhlotsheni eziningi zokusebenza.

Le bhawodi lenziwe ngensimbi yekhwalithi ephezulu, le bhawodi yakhelwe ukumelana nezindawo ezinzima, ukucindezeleka okuphezulu nemithwalo esindayo. Ikhanda eliyi-hexagonal lihlinzeka ngokulingana okuvikelekile nokuqinile, kuyilapho intambo ivumela ukufakwa nokususwa kalula.

Ilinganisa u-6mm kuya ku-100mm ubude, le bhawodi itholakala ngebanga losayizi ukuze ivumelane namaphrojekthi nezidingo ezahlukahlukene. Kungakhathaliseki ukuthi wakha umshini, umisa isakhiwo noma uhlanganisa izinto zokusebenza ndawonye, leli bhawodi linikeza amandla nokuqina okudingayo ukuze wenze umsebenzi wenziwe.

Ngaphezu kwalokho, iCarbon Steel Hex Bolt Din 933 kulula ukuyinakekela futhi ayiwohloki kalula ngokuhamba kwesikhathi. Lokhu kusho ukuthi ungathembela ekusebenzeni kwayo iminyaka ngemuva kokufakwa.

Kulabo abafuna ibhawudi elithengekayo nelisezingeni eliphezulu, le carbon steel bolt iyisinqumo esihle. Akugcini nje ngokuqeda isidingo sezixazululo ezibizayo neziyinkimbinkimbi zokubopha, kodwa futhi kulula ukuzifaka nokukhipha, zikongela isikhathi esibalulekile nomzamo.

Kafushane, iCarbon Steel Hex Bolt Din 933 iyisisombululo esinokwethenjelwa nesisebenzayo sokubopha esingasetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza. Idizayinelwe ukuqina okuphezulu nokusebenziseka kalula, okuyenza ikhethelwe onjiniyela, abakhi kanye nabathandi be-DIY ngokufanayo. Thembela kuCarbon Steel Hex Bolt Din 933 ukuze ikunikeze isisombululo esimaka wonke amabhokisi, kungakhathaliseki ukuthi iyiphi iphrojekthi osebenza kuyo.